ResinLab’s line of edge fill products are epoxy syntactic foams that utilize glass and/or polymeric microspheres to reduce density and improve machinability. They provide excellent protection against water, humidity, salt spray, and other chemicals, passing the FAR 14 CFR Part 25.853 (a) 60 second vertical burn test. All ResinLab edge fill products are formulated to a simple 2:1 mix ratio for use in side-by-side cartridges or meter mix and dispense equipment.

- Low density syntactic foams ranging in cured specific gravities of 0.55 to 0.70 grams/cc.

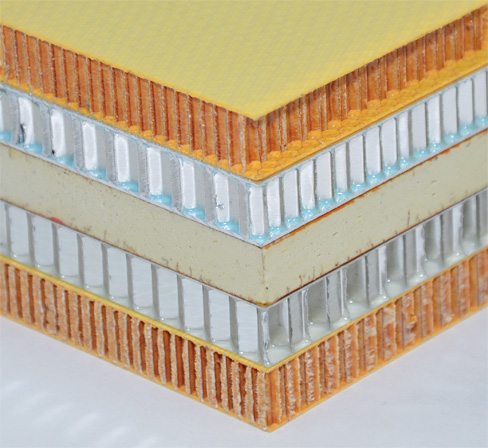

- Filled with high burst strength hollow glass microspheres that are designed to provide structural strength, as well as smooth edges to aircraft interior honeycomb panels.

- Designed to be applied in smooth non-sag beads.

- Flame retardant and certified to FAR 14 CFR Section 25.853(a) vertical burn test.

- Unique color for easy identification and differentiation.